Specification:

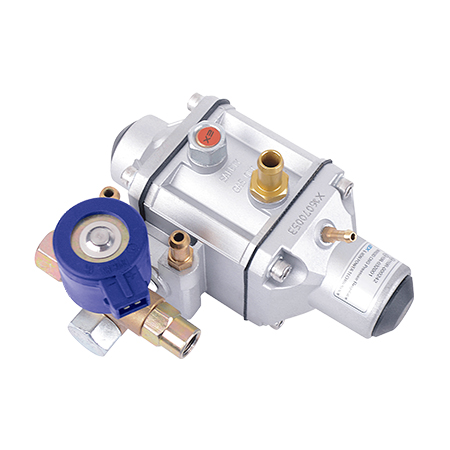

A two-stage compensated membrane pressure regulator with a water/gas heat exchanger, filter, high pressure gas solenoid valve and safety valve.

Two sides have fixing points, enabling the reducer to be installed practically in any position.

All connectors are on the same side for easier installation.

1. Two grade diaphragm with inlet pressure compensation makes output pressure more stable.

2. Heat channels connected to the engine cycle meets differenct weather.

3. With high pressure solenoid valve, safety valve, more secure.

4. Two sides with a fixed point, can be installed in any position.

5. All interfaces are in the same plane, the installation more convenient.

Installation:

1. The pressure reducer should be installed on a location in the engine compartment with small vibration and where it is easy to fix. It should not be installed directly on the engine. Install the high pressure solenoid valve perpendicular to the ground.

2. After the reducer is installed, connect the circulating water pipe of the engine to the heating water passage of the reducer. Ensure that the heated water can be fully circulated. Usually, the heated circulating water is taken through the engine temperature sensing plug connector and the water tank drainage switch.

3. Before installing the pressure reducer, slightly open the cylinder valve to remove dirt to prevent dust and moisture into the pressure reducer. When opening the cylinder valve, do not target the outlet of the cylinder valve to the operator or others to prevent hurting people because of the high pressure gas suddenly rushing out.

4. When disassembling and replacing the pressure reducer, turn off the cylinder valve first, and discharge the high pressure gas in the pipeline through the inflation valve before disassembly.